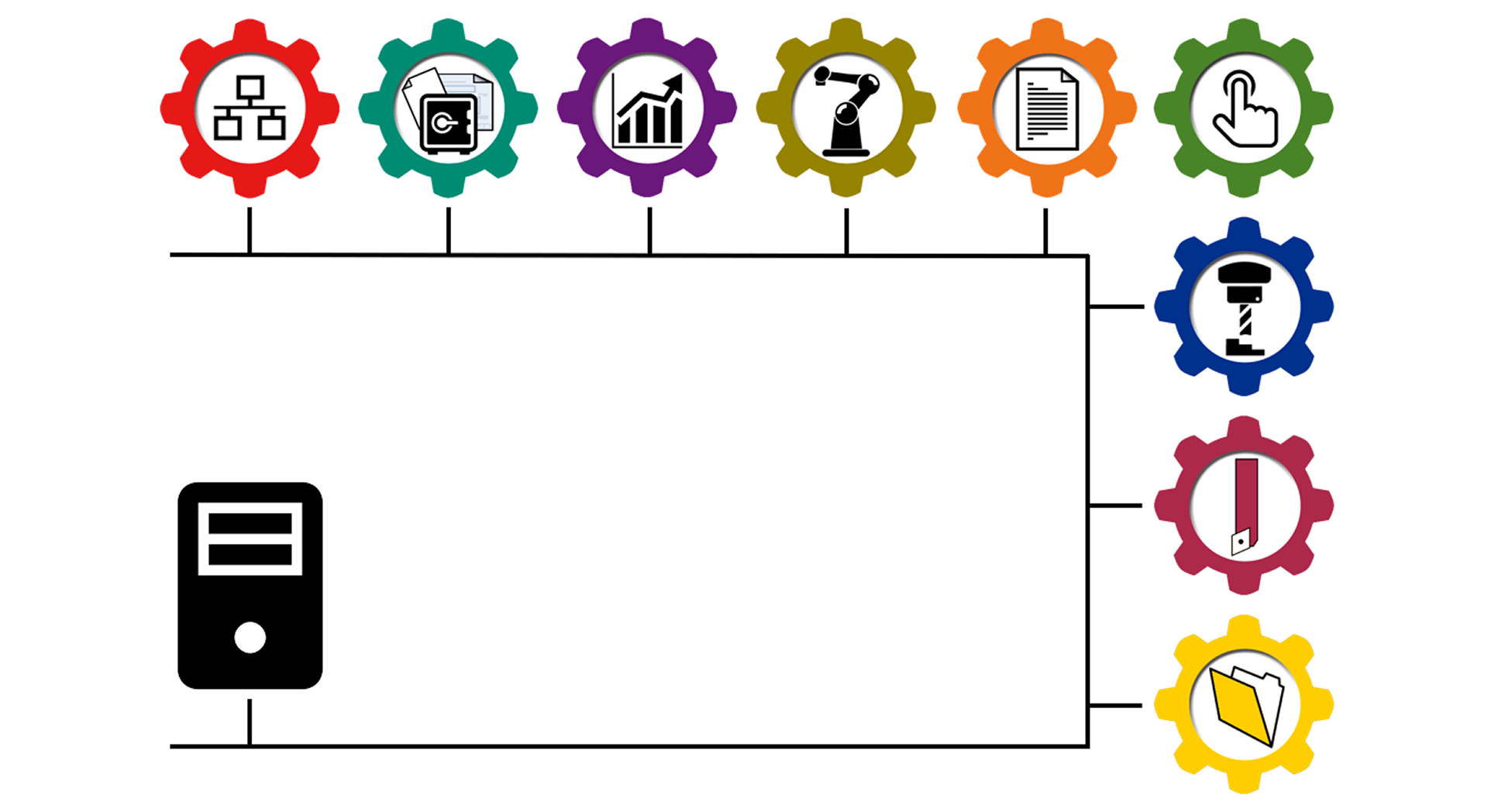

Automate your shop floor with Predator Software applications

- Network CNCs, Robots, CMMs & PLCs

- Wired & Wireless

- Ethernet, RS232 & Parallel

Predator DNC software provides an industrial network for CNCs, robots, CMMs, PLCs, part markers, tool presetters & test stands.

Learn more- Production Data Management

- Paperless Manufacturing

- Revision Control & Workflow

Predator PDM software is designed to control manufacturing and quality documents with vault(s), revision control & statuses.

Learn more- Automatic Data Collection

- Machine Monitoring & OEE

- Dashboards, Charts & Reports

Predator MDC software is real-time machine monitoring, dashboards, KPIs, OEE and manufacturing data collection.

Learn more- Flexible Manufacturing System

- Lights Out Production

- Run Schedules of Small-Large Lots

Predator RCM software is a flexible cell controller and scheduler designed to automate manufacturing processes.

Learn more- Compare & Edit G Code

- Basic DNC

- 3D Backplotting & Animation

The Predator CNC Editor software improves the quality, capability and performance of CNC programs.

Learn more- Machine Simulation & Verification

- 2-5 Axis Mills, Lathes & Mill/Turns

- Actual CNC Code

Predator Virtual CNC software is designed to simulate and verify operation of a wide range of CNC machines.

Learn more- Tool, Gage & Fixture Management

- Bar Code, QR Code & RFID Support

- Check In & Check Out

Predator Tracker software is designed to manage, organize and automate the tracking of tools, gages & fixtures.

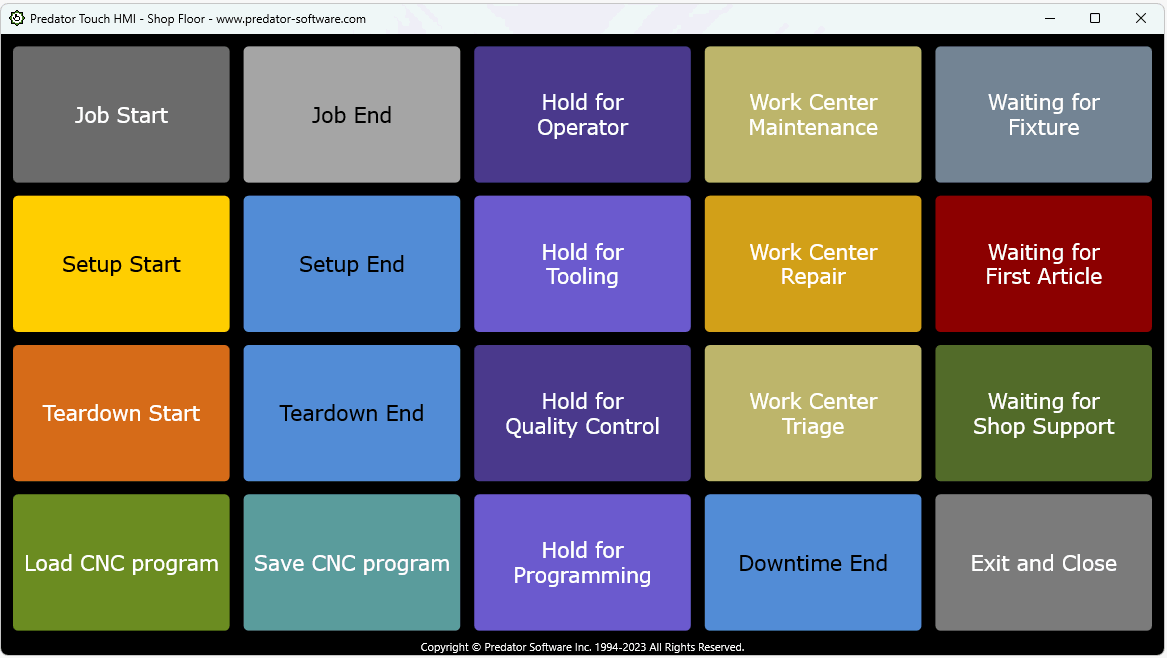

Learn more Predator Touch HMI

Predator Touch HMI

- Create Shop Floor Applications

- Touch Friendly User Interfaces

- Code Free Designer

Predator Touch HMI is touch friendly software which replaces bar code readers, QR code readers & hand held terminals.

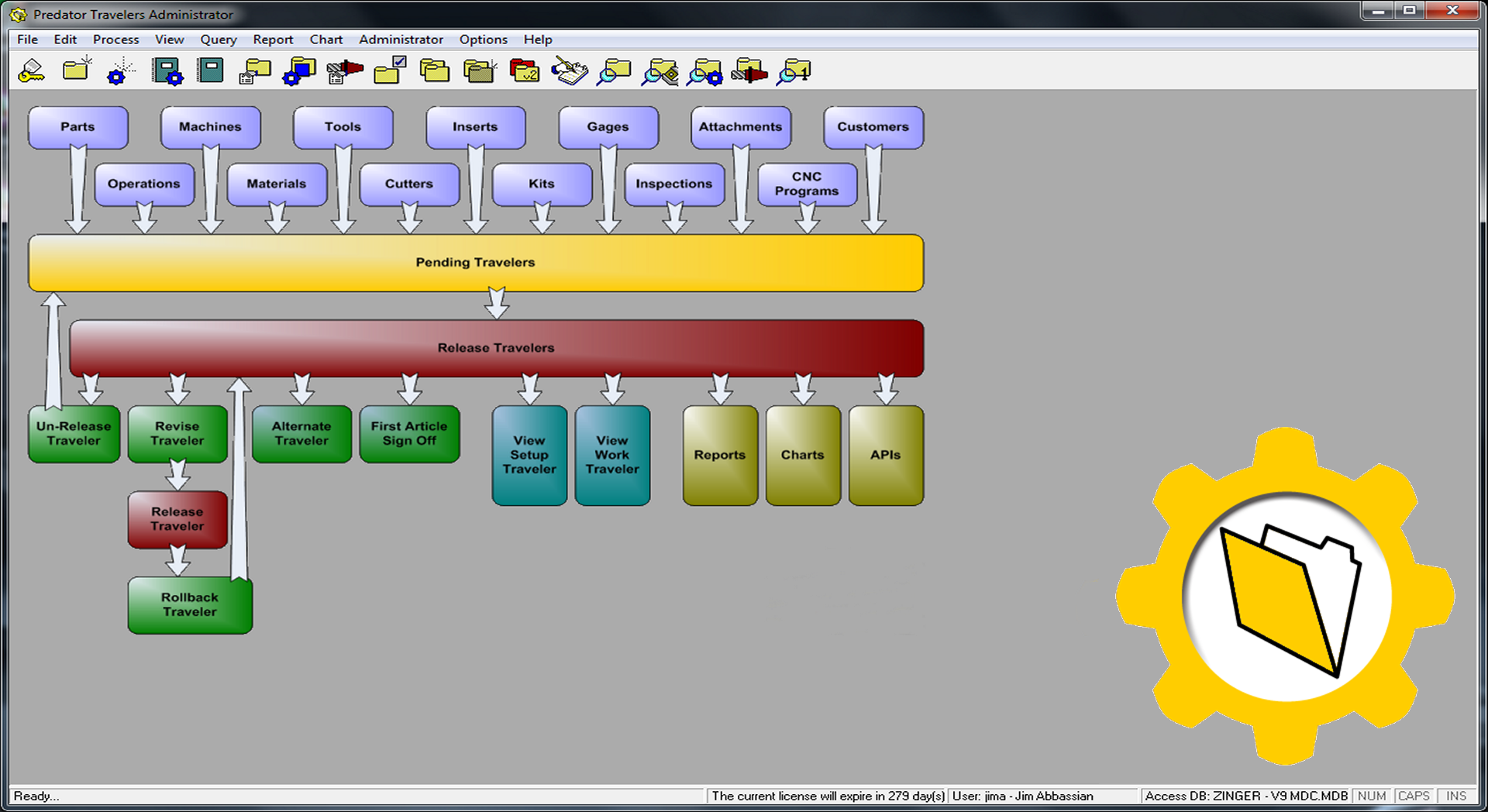

Learn more Predator Travelers™

Predator Travelers™

- Electronic Work Instructions

- Paperless Manufacturing

- Revision Control & Workflow

Predator Travelers software is designed to manage work instructions with an option for paperless shop floor productivity.

Learn more Predator FLM™

Predator FLM™

- Floating Network Licensing

- Concurrent Licensing not per User

- Windows Service

Float Predator software applications within your wired or wireless network to manage, control and reduce licensing costs.

Learn more Predator Secure applications

Predator Secure applications

- Predator Secure DNC™

- Predator Secure PLC™

- Predator Secure MDC™ and more

Secure industrial Ethernet networking of Windows based CNC machines, robots, CMMs, PLCs, 3D printers & more.

Learn more Predator Utilities™

Predator Utilities™

- Predator Import Service™

- Predator MDC Export Service™

- Predator File Parser™ and more

Utilities that supplement Predator implementations. Often Predator Utilities are bundled with Predator Services.

Learn more